METAL SHELVING AND RACKING DEALERS

Are you a metal racking units retailer?

Cremonini can boast a corporate history that began in 1965 in Crevalcore, where our factory is still located.

Since 2002, our quality system has obtained certification according to the ISO 9001:2000 standard, issued by the authoritative TUV body.

Why become a Cremonini shelving dealer?

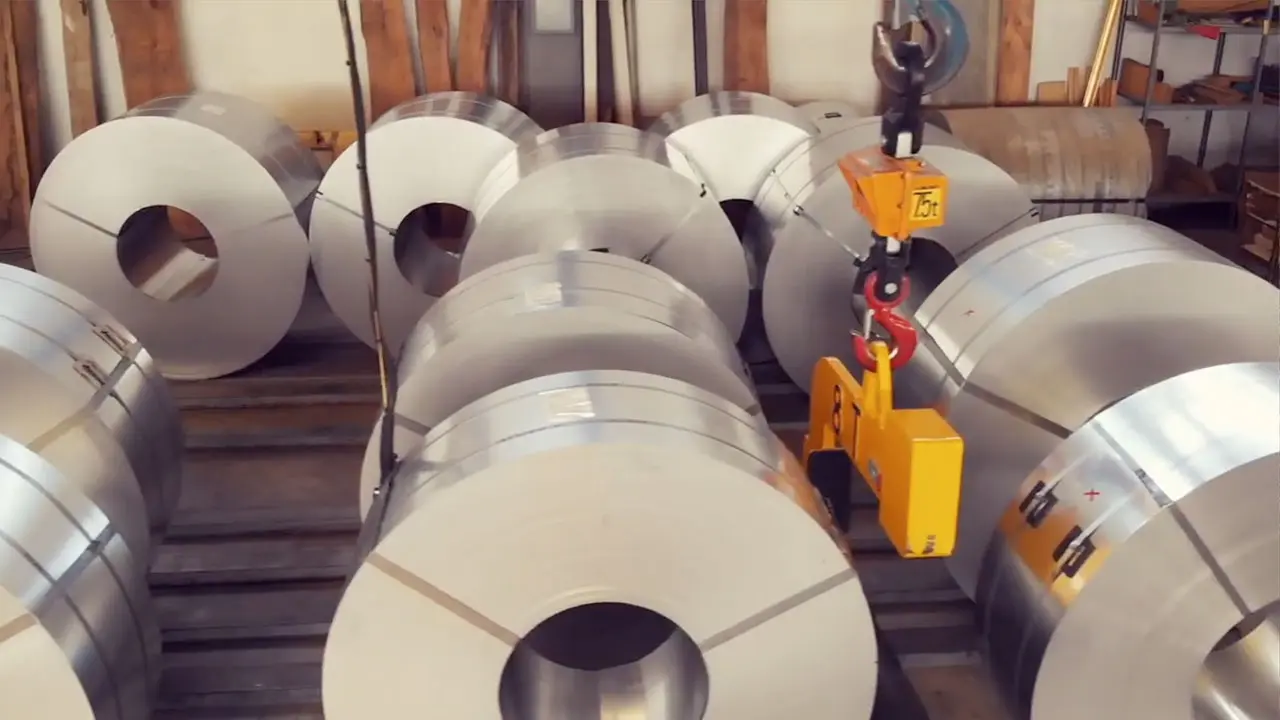

The raw materialswe purchase come directly from the best steel mills.

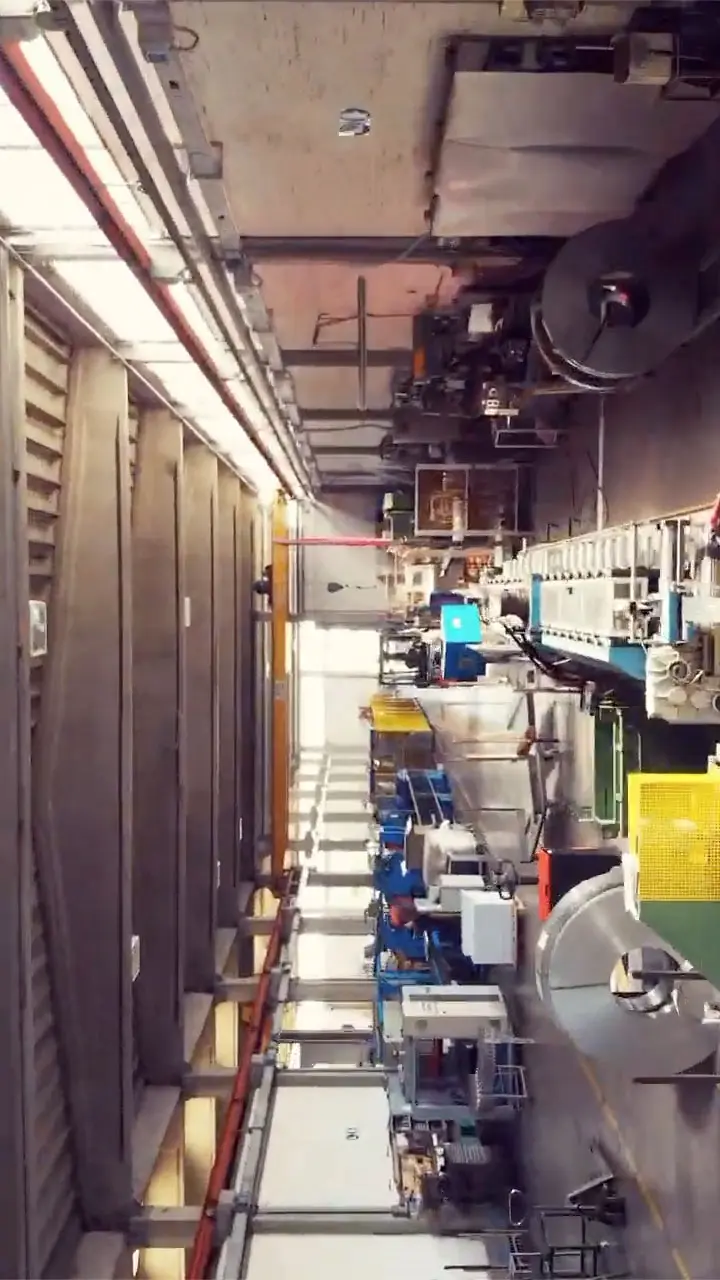

Our production department, thanks to rapid production processes, is able to produce large batches with extremely short delivery times.

We respond promptly to requests for quotes: within one day of receiving the request, with customized layouts via AUTOCAD, we deliver the material via express courier or with dedicated qualified carriers.

Among the services offered, we include the possibility of carrying out joint inspections at the end customer's premises, to study together the best solution based on the required project requirements.

We can take care of the assembly of the products directly on site, also relying on qualified suppliers, depending on the geographical distance or the quantity in place.

Therefore, if you are interested in becoming a reseller of Cremonini metal shelving and in establishing a relationship with a reliable, punctual, fast partner capable of guaranteeing high product quality over time, as well as an effective and continuous after-sales service, do not hesitate to contact us: we will study together the best solution to satisfy your needs.

Materials

Raw

The raw material we purchase comes directly from the best steel mills. We carry out rigorous controls starting with raw materials and supporting materials, directly at acceptance, upon their arrival in the warehouse. The controls are then extended to all processes and continue from the request for quotation, to the fulfillment of the order.

Ready

Delivery

Our resellers of metal shelving or racking can count on a wide availability of goods for prompt delivery, thanks to a warehouse area of 1,500 square meters of product, ready to be shipped.

Rapidity

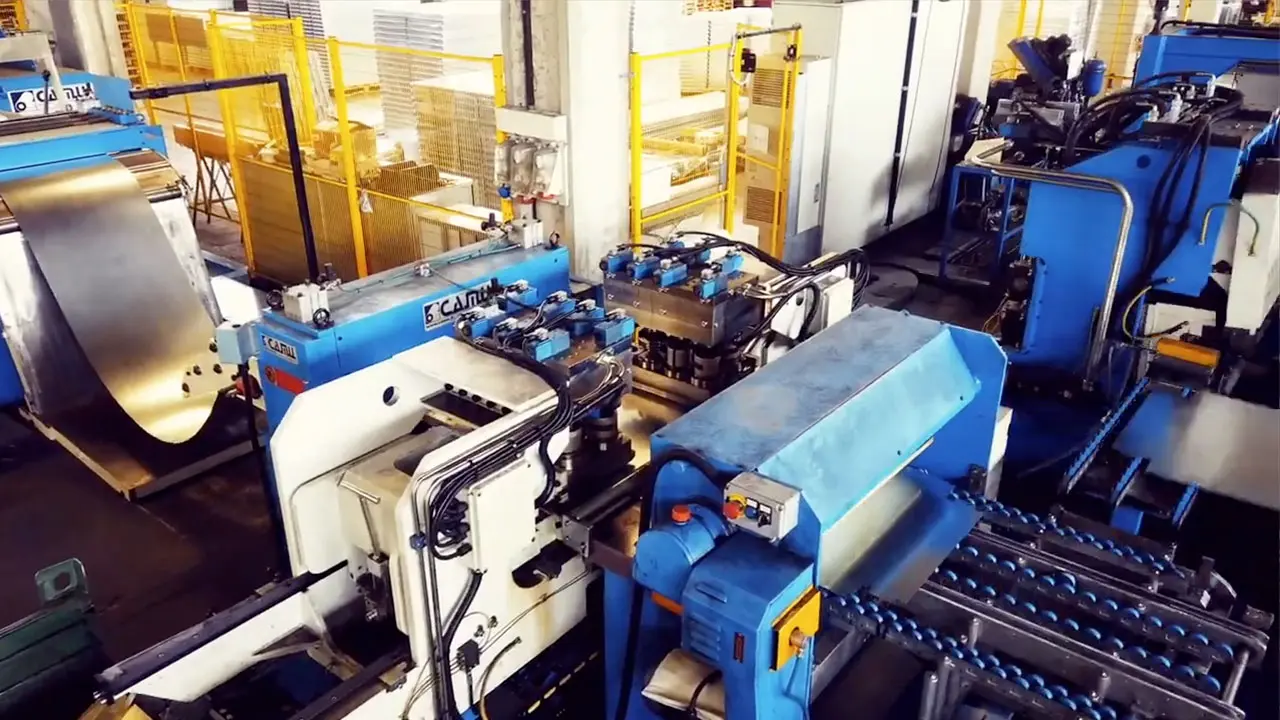

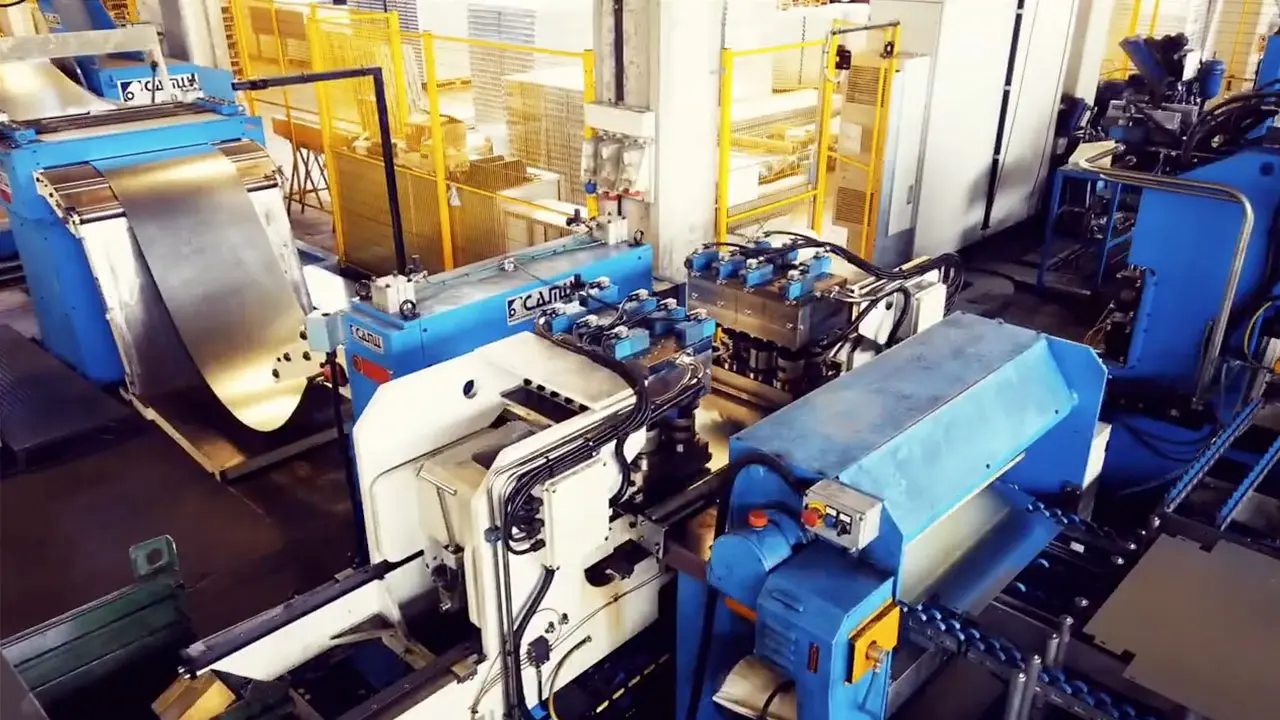

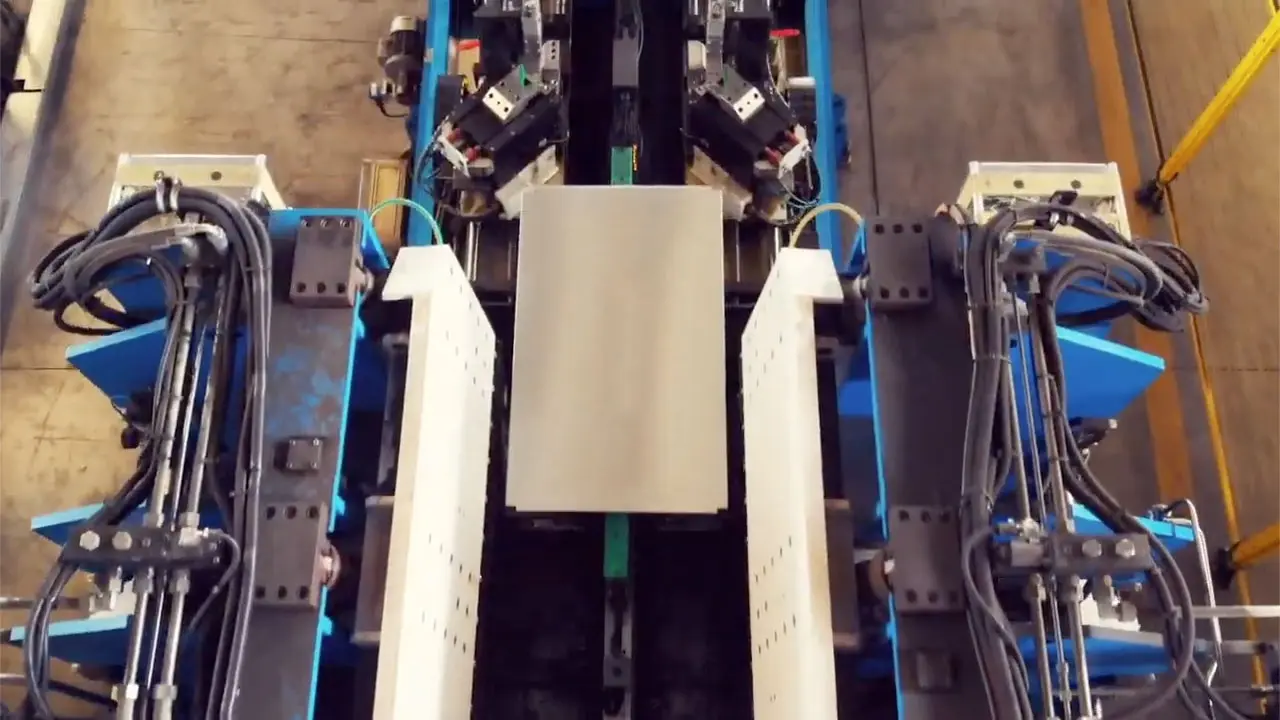

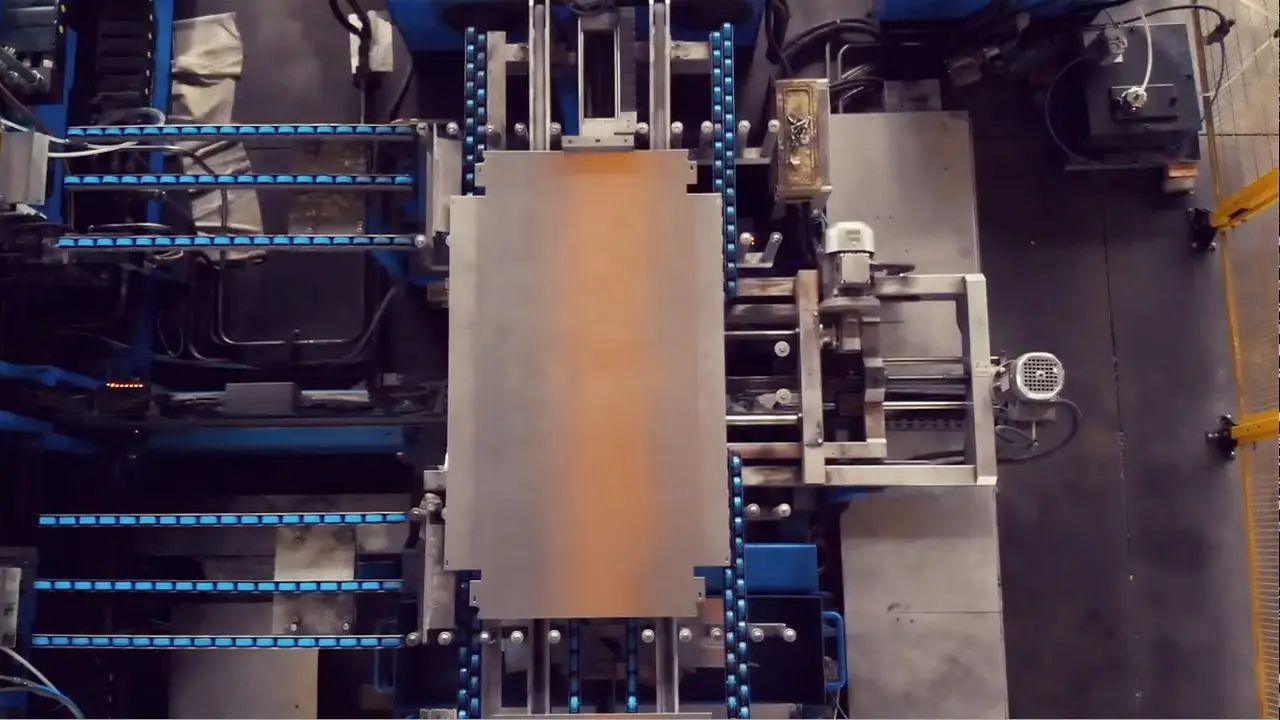

Our production department is able, with rapid production processes and automatic sheet metal stamping and bending machines, to achieve the production of even large batches with extremely short lead times even for specially designed and manufactured completion accessories.

Quotes

in 24h

We respond promptly to requests for quotations, within one day of receiving the request, including customized layouts via AUTOCAD.

Customized

Solutions

Our services include the ability to conduct joint inspections at the end customer's site to jointly study the best solution based on the project requirements.

Assembly

We can take care of the assembly of products directly on site, within the end customer's plant, also relying on qualified suppliers, depending on the geographical distance or quantity involved..